Socket Casting, Positive Mould, and Rectification

The prosthetic socket is the primary interface between the amputee’s residual limb and the ground and therefore a good, comfortable fit is required to ensure a positive outcome is reached in an amputees rehabilitation[1].

The prosthetist takes the measurements for the socket using plaster bandages to create a cast (Casting). The cast created is filled with plaster powder to create a positive mould (Positive Mould). The positive mould is then modified to optimize the socket fit, this process is called “rectification” (Rectification). The socket is then shaped over the mold to create the custom socket, this is referred to as a laminated socket. A “check”/test/diagnostic socket is sometimes fabricated before creating the definitive socket (this socket is usually transparent, allowing the clinician a complete view to evaluate the fit and make changes). Multiple fittings are at times necessary to assure the best possible design with a comfortable and effective fit. Generally sockets are made out of plastic, either thermoplastic or with thermosetting, called laminated sockets. Laminated sockets can be reinforced with fibre glass, carbon fibre, or nylon[2].

Because it is the interface between the device and residual limb, the quality of the socket design, whatever the model used, is key and decides on user’s comfort and his/her ability to control the appliance. A user will never walk properly and will never reach the agreed goal of the rehabilitation plan if the quality of the socket fit is not satisfactory regardless of the material used (plastic, resin or carbon). The quality of the fit depends entirely on the work of the prosthetist and his/her capacity to insure precise measurements during casting and suitable rectification of the positive mould to distribute forces over the socket where needed.

Other methods:

- [5]

- A more sophisticated and expensive technique utilized today is a CAD system (Computer Aided Design). With the improvement of technology

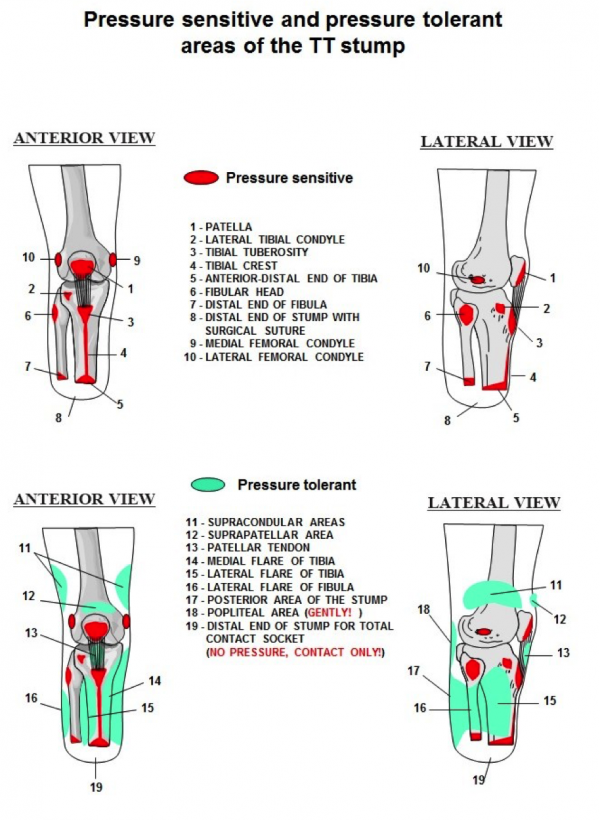

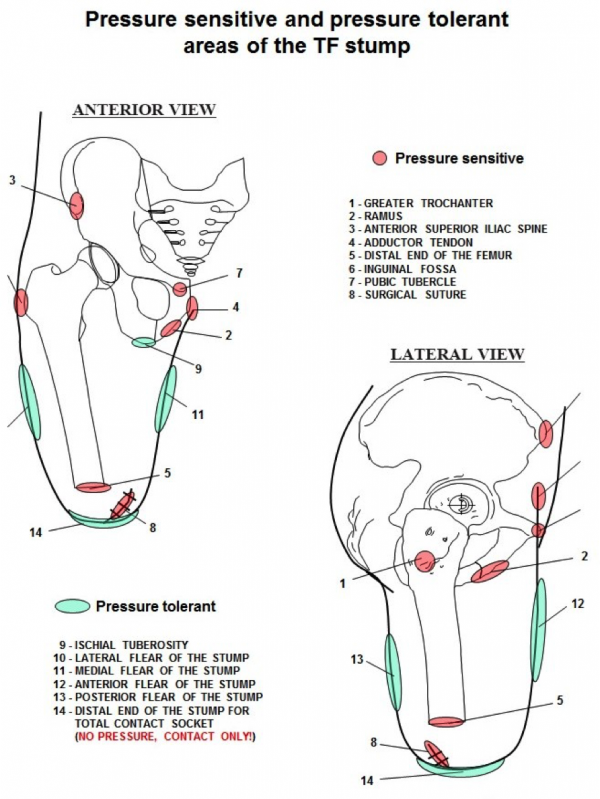

Pressure tolerant and pressure sensitive areas:

The prosthesis applies forces over the body. The amount, the location of their application and the means that control those forces contributes to the impact the prosthesis has on mobility, function, and acceptance of the device. Pressure distribution over a greater surface diminishes the load and provides more comfort during the use of prosthesis.

Although the majority of the stump areas are considered as pressure tolerant, some are very sensitive and cannot support any pressure.

Attention:

Very short TT stumps (shorter than 20% of the anatomical length) are insufficient for providing adequate control over the prosthesis and supporting the body weight. Nevertheless, the quality of the stump is more important than its length.

It is obvious that to be able to fit the stump into the prosthesis: taking into consideration all those preconditions mentioned before, it will be necessary to count on the principal element of the prosthesis – the socket. The later serves as an interface between user and device and due to that has to respond to the physical-anatomical demands of the patient, to the mechanical specificities of components and to the biomechanical requirements of the gait.

Below we describe some common TT and TF socket designs.

Transtibial Sockets

Patellar Tendon Bearing

| Socket PTB (Patellar Tendon Bearing)

The weight bearing takes place below the patella, at the patellar tendon. The suspension is generated by a belt that is tightened around the distal part of the thigh. The tension of that belt limits the blood and lymphatic circulation; moreover, after long term use results in muscle atrophy and other related problems. |

|

| Socket PTB SC (Patellar Tendon Bearing Supracondylar)

The weight bearing takes place below the patella, at the patellar tendon. The suspension is generated at the medial and lateral areas of the femoral condyles. Compared to the PTB socket with belt suspension, this design does not produce problems of blood circulation or atrophy. For the moment, this type is used worldwide as most basic design for prosthetic fitting of medium and long stumps. |

|

| Socket PTB SC SP (Patellar Tendon Bearing Supracondylar Suprapatellar)

The weight bearing takes place below the patella, at the patellar tendon. The suspension is generated at the medial and lateral areas of the femoral condyles and at teh suprapatelar area. This type is indicated for short stumps, as well as in cases of antero-posterior instability in the knee. |

Indications

Primary Amputees – The PTB socket is good for primary amputees as the socket can be modified to accommodate the changes in the residual limb that occur for 12-18 months after the amputation.

- Sensitive Residual Limbs – If the amputee has a particular area of sensitivity on their residuum it is possible in a PTB socket to relieve these areas more easily than in a total surface bearing style socket.

- Bulbous Residual Limbs – The construction of a PTB socket, an inner liner and outer hard socket, allows for build-ups to be applied to the inner liner allowing easier donning and doffing for an amputee with a bulbous residual limb

- Poor Hand Dexterity/ Poor Eyesight/ Hemiparesis – PTB sockets are much easier to don/doff than total surface bearing sockets

Contraindications

- Active amputees can find the PTB trim lines and suspension methods too restrictive, especially with regards to knee flexion.

- Some amputees can find the PTB prosthesis pistons (Total surface bearing sockets

Socket SSS (Silicon Suction Socket) The weight bearing takes place all over the stump surface. The suspension is generated by means of tight adhesion/friction between stump and silicon liner that has a pin at its distal part. This pin is installed in a blocking mechanism inside the prosthetic components, or using a suction mechanism, hence insuring the suspension. Indicated for all types of stumps.

- TSB sockets “uniformly distribute weight over the entire residual limb” which therefore “delivers a minimal skin pressure”[8].

- TSB sockets are volume matched to the residual limb with 100% surface contact during the gait cycle.

- Successful fitting of a TSB socket requires good control of the soft tissues, minimised pressure peaks and distribution of load over the maximum surface area available[9].

Advantages and Indications

- Active amputees benefit from the lower trim lines possible with the TSB style design[8][10] .

- TSB sockets reduce pistoning of the socket ([11]

- Proprioception is increased due to weight bearing over the entire residual limb and good pressure distribution by the socket walls, which in turn enables the amputee to have better balance with eyes open or closed[11]

- Suspension of the TSB socket is also noted to be better than the PTB design as it is integrated in the socket using locking pins or suction[11].

- Due to the entire surface of the residual limb accepting weight in the TSB socket it is believed that these sockets are more comfortable because overall socket pressure is reduced[12].

Disadvantages and Contraindications

- TSB sockets are not suitable for primary amputees due to volume changes in the first 12-18 months post-amputation[13]. For the same reason TSB sockets are also not suitable for amputees undergoing treatments such as dialysis due to volume fluctuation

- Unsuitable for patients with short residual limbs, less then 10cm long, which require higher trim lines for stability around the knee[10].

- Some amputees may experience pain at the distal end of their residual limb due to the way a TSB/HST socket weight bears over the entire limb[13]. Also patients with excessive soft tissue may drop down into a TSB/HST socket too much which will cause pain at the distal end[13]. Amputees with bony spurs are also not suitable for TSB/HST sockets[13].

- Discomfort during knee flexion may result due to the silicon liner bunching up in the popliteal region[14]

- Increased perspiration may result due to the silicon liner, which can lead to irritation of the residual limb[14]

- TSB/HST sockets are not indicated for amputees with visual/sensory disturbances or Hemiparesis as they are more difficult to don/doff than a PTB design[13].

- Amputees with excessive soft tissue may find they get discomfort upon knee flexion due to creasing of the silicon liner[13]

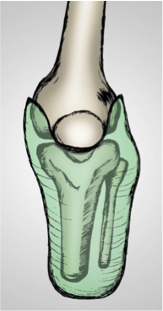

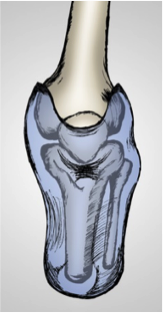

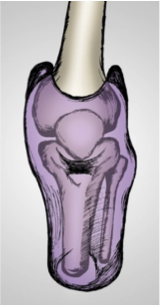

Transversal view shows the differences between the internal shapes of PTB SC v SSS sockets.

Socket PTB SC Socket SSS Transfemoral Sockets

For TF sockets, the designs mostly used at present are the followings.

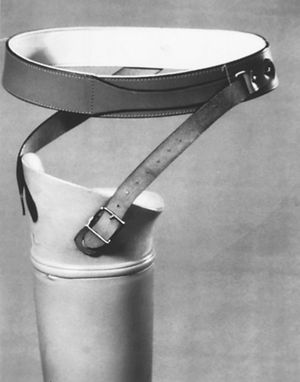

Quadrilateral Socket

The weight bearing takes place at the ischial tuberosity by the means of ischial support at the posterior shelf of the socket. The suspension is provided by negative pressure (suction) that is generated by adequate fitting of the socket over the stump. In some cases, the suction suspension can be complemented by the use of the belts (Silesian, Neopren, etc.).

For the moment, this type of socket is in most use for all types of stumps.

Transversal view Medial view Posterior view Ischial Containment Socket

The weight bearing takes place all over the surface of the stump without localizing one specific point; hence, generating more comfort, better control over the prosthesis and security for the user. The ischial tuberosity does not suffer from direct, complete and permanent weight bearing. The principal peculiarity of this design, apart of the exact volume determination, is the medial wall/border of the socket that contains the ischial ramus. The suspension is provided by negative pressure (suction) generated by adequate fitting of the socket over the stump.

For the moment, this type of socket is in worldwide promotion, replacing the quadrilateral one.

Transversal view Medial view Posterior viewTransversal view Medial view Posterior view Suspension Systems

This is a crucial factor in the design of a prosthesis. The suspension is how the socket kept on the residual limb preventing it to fall off when the leg is lifted up or moved during gait. Good suspension will improve the energy transfer, enhance the control of the prosthesis, and decrease any discomfort or abrasions. When suspension is poor the leg will feel heavy and may lead to skin breakdown. For suspension prescription the patient will need to be thoroughly assessed not just with regard to the residuum shape and length, but also their overall strength, hand dexterity, eye sight, and balance in standing. [2]

1.Cuffs, Straps and Belts [17]

Also called Auxillary suspension. This is the original way of keeping the socket on and prevent it from falling off during the swing phase. Even though this and “old” way of suspension it is still used today as it is an inexpensive, simple, reliable and durable way of suspension. This can vary from a simple soft strap/cuff to a very rigid band around the pelvis.

- Transtibial: With PTB sockets there can be a strap over the patella.

- Transfemoral: Belts or straps can be used as a primary suspension method if other methods fail or are not appropriate. It can also be used as a secondary option for when negative pressure or suction is used. It is also indicated for an individual with a short residuum, who have changing volume of their residuum, this keeps the socket on even if the socket fit is loser at the end of the day or poor hip abductor strength. Disadvantages: It is warm, pressure around the pelvis area, needs good hand dexterity and strength, moves when sitting, uncomfortable, provides minimal suspension, can cause bruising or chafing.

2. Lanyard[17]

This is when a cord or strapped is attached to lower end of the liner. As the individual inserts the residuum with the liner on the cord/strap will go through a small hole in the bottom of the socket. The cord is then pulled tight, to draw the residuum into the socket. The lanyard is then attached with a mechanism on the outside of the prosthesis to keep it secure. Used for transfemoral suspension.

- Advantage: Easy to don (put on) the prosthesis in a seated position, especially for someone with poor eyesight or balance. It provides a secure suspension and decreases socket rotation. Inexpensive, simple, and reliable.

- Disadvantages: Needs some hand dexterity and strength. A liner is needed for suspension.

3. Self Suspending Socket[17]

This is when the suspension is created by the socket brim (top part) on the residuum. The brim part is made to extend and narrow over the joint (example over the knee joint) in order to create a grasp or hold over the joint. An example of this is the Patellar Tendon Bearing Supracondylar Socket. Only for transtibial suspension. Poor Suspension. For more information read the part Patellar Tendon Bearing Sockets higher up on this page.

4. External Sleeve[17]

A sleeve that fits snugly over the socket and then extends onto the individual’s thigh is used to seal in the air in the socket and in that way create a suspension. Sleeves are made from different materials including neoprene, silicone or copolymer gel. Mostly used with transtibial sockets.

- Advantage: Pistoning (movement of the residuum inside the socket) is reduced with an airtight seal. Sleeves are flexible and usually allows the knee to bend (if the sleeve has a ribbed or wave design over the knee joint) and it is cosmetic as it covers the top edge of the socket. It is a reliable form of suspension and relatively inexpensive.

- Disadvantages: Sleeves without a ribbed or wave design can cause abrasion over the patella. If applied incorrectly the person can get a skin irritation where the sleeve touches the skin. Needs hand dexterity and strength. The sleeve’s effectiveness is reduced with wear and tear, a hole in the sleeve can lead to a loss of suction.

5. Pin and Lock[17]

A silicon or gel liner with a pin at the bottom of the liner is used on the residual limb. When the limb is placed into the socket the pin has to go into a locking mechanism at the bottom of the socket. This mechanism will lock the pin in place, creating a secure suspension in the socket. It is used in both transfemoral and transtibial prosthetics. A release mechanism can be pressed to unlock the pin.

- Advantages: Helps people to “pull” the residuum into the socket by turning the outside mechanism until the pin is locked. Relatively easy donning and doffing and can be done in a sitting position. More forgiving with volume fluctuations.

- Disadvantages: Due to the pulling down action of the pin on the liner an elongation effect can happen at the bottom of the residuum and cause skin breakdown, but newer liners are reinforced with a matrix to avoid this from happening. More expensive and heavier than previously mentioned options. Wear and tear on liners. When the pin is misaligned or the liner is donned incorrectly the locking mechanism will not be engaged, this might be difficult for someone not having the ability to bend down or with poor eyesight.

6. Suction without a liner[17]

The socket is made with an expulsion valve that will let air out to create a seal once the residuum is in and the valve is closed. The suction is created between the bare skin and the inside of the socket. To achieve this, the individual will have to pull the residuum into the socket using a piece of material, a special sock, cord or webbing. By opening or pushing on the suction valve the air will return, breaking the seal and thereby releasing the residuum to remove the prosthesis.

- Advantage: With an accurate fit the suspension will be very good. Less expensive than options with liners

- Disadvantage: When the socket is donned poorly the suction will not hold and there will be poor suspension. It is an old way of suspension. Donning can be complex for some individuals as it requires hand strength and dexterity as well as balance in standing. Not secure suspension with volume fluctuations or if there is a failure with the valve.

7. Suction with a liner [2][17]

A liner that is donned on the residuum is used to create suction instead of the skin suction described above. These liners are usually made of silicon or gel, to create a seal with the inside of the socket the liner can have silicone rings/ribs or a membrane. The air can escape through the valve as the socket is donned and will keep the suction once the valve is closed. Some sockets have a one way valve. By opening or pushing on the suction valve the air will return, breaking the seal and thereby releasing the residuum to remove the prosthesis. Lubricant or an alcohol solution on the seal will help the liner to slide in and to create a seal. When using suction with a liner an external sleeve is not necessary, unless there is severe volume fluctuations. The liner is usually covered with material to help it last longer.

- Advantage: Even pressure throughout the socket. Secure fit. Donning in a seated position is possible. Used to stabilize excess residual tissue. Good suspension even with small volume fluctuations. Liner and socket donning does not have to be as precise to secure suspension but may cause rotation in the socket.

- Disadvantage: Relatively expansive. Wear and tear on liners. Poor suspension with significant volume fluctuations. Good hand strength and dexterity needed. Lubricant is needed for donning.

8. Vacuum-Assisted Suspension[17]

Also known as Negative Pressure, Elevated Vacuum or Dynamic Vacuum. Suction suspension is created with direct contact between the liner (or with the membranes on the liner) and the socket wall. With this system a mechanism/pump sucks the air out between the liner and the socket creating a negative pressure that is the same across the entire surface. To seal off the system an external sleeve or seal is used at the top of the socket.

- Advantage: The mechanism creates a constant negative pressure and allows for better suspension when there is volume fluctuation. Less pistoning and rotation occur within the socket.

- Disadvantage: More expensive. Mechanical components that can break. Adds weight to the prosthesis.

9. Osseointegration[17][20]

This procedure can be done on patients with a short above knee amputation. An implant is placed within the remaining femur bone. When it is healed and the bone attached to the implant an osseointegrated prosthesis can be directly attached to the implant in the bone. No need for a socket or liner.

- Advantages: Physiological weight bearing, better mobility because the socket is not restricting. Easy donning and doffing. Osseoperceptive sensory feedback that allows for more precise control over the prosthesis.

- Disadvantages: Cost of surgery and specific components for the prosthesis. Risk of infection and other complications such as delayed wound healing or bodily fluid leakage from the implant. Extensive rehabilitation is needed. With some implants no weight bearing is allowed for 6 months.

Stump Socks

Stump socks can be added over the residuum or over the liner to provide additional circumference if the residuum change in volume. This will prevent movement within the socket, peak pressure points, and chafing. Socks can be made in different thicknesses from different materials like wool, cotton, nylon or socks impregnated with gel.

References

- ↑ Fergason J and Smith D.G (1999) Socket Considerations for the Patient With a Trans-Tibial Amputation Clinical Orthopaedics and Related Research 361 pages76-84

- ↑ 2.02.12.2 Engstrom B, Van de Ven C, editors. Therapy for amputees. Elsevier Health Sciences; 1999

- ↑ AmputeeOT: How a test prosthetic socket is made. Available from: ↑ Shriners Prosthetics BK socket lamination. Available from: ↑ Normann E, Olsson A, Brodtkorb TH. Modular socket system versus traditionally laminated socket: a cost analysis. Prosthetics and orthotics international. 2011 Mar 1;35(1):76-80.

- ↑ ICRC PRP Cambodia Battambang’s Prosthetic Workshop Transtibial Prosthesis . Available from: ↑ Össur Presents: Modular Socket System. Available from: ↑ 8.08.1 Kahle J.T (1999) Conventional and Hydrostatic Transtibial Interface Comparison Journal of Prosthetics and Orthotics 11(4) 85-91

- ↑ Muller M, Staats T.B, Leach M and Fothergill I , ↑ 10.010.1 Söderberg B (2002) Technical Note: A New Trimline Concept for Trans-Tibial Amputation Prosthetic Sockets Prosthetics and Orthotics International 26 159-162

- ↑ 11.011.111.2 Yiğiter K, Şener G and Bayar K (2002) Comparison of the Effects of Patellar Tendon Bearing and Total Surface Bearing Sockets on Prosthetic Fitting and Rehabilitation Prosthetics and Orthotics International 26 206-212

- ↑ Moo E.K, Osman N.A.A, Pingguan-Murphy B, Wan Abas W.A.B, Spence W.D and Solomonidis S.E (2009) Interface Pressure Profile Analysis for Patella Tendon Bearing Socket and Hydrostatic Socket Acta of Bioengineering and Biomechanics 11(4) 37 – 43

- ↑ 13.013.113.213.313.413.5 Hachisuka K, Dozono K, Ogata H, Ohmine S, Shitama H, Shinkoda K (1998) Total Surface Bearing Below – Knee Prosthesis: Advantages, Disadvantages and Clinical Implications Archives of Physical Medicine and Rehabilitation 79 783-789

- ↑ 14.014.1 Sewell P, Noroozi S, Vinney J and Andrews S (2000) Developments in the Trans-Tibial Prosthetic Socket Fitting Process: A Review of Past and Present Research Prosthetics and Orthotics International 24 97-107

- ↑ Cornerstone Prosthetics and Orthotics. What Are Your Above Knee Amputee Options? Available from: ↑ Bulow Orthotic and Prosthetic Solutions. Prosthesis Suspension Types Available from: ↑ 17.017.117.217.317.417.517.617.717.8 NZALS Peke Waihanga, Aotearoa. Suspension Systems. ↑ Ottobock. How to put on a below knee prosthesis with one-way valve and knee sleeve?Available from:↑ Ottobock. How to put on an above knee prosthesis with Pin Liner (Shuttle Lock System)? Available from: ↑ Li Y, Brånemark R. Osseointegrated prostheses for rehabilitation following amputation. Der Unfallchirurg. 2017 Apr 1;120(4):285-92.

- ↑ AmputeeOT: Liner Primer! All about liners for prosthetic legs Available from: ↑ AmputeeOT: All about stump socks for below knee amputees. Available from: